Badcock And Wilcox Boiler Pptv

- Babcock And Wilcox Boiler Ppt Download

- Babcock And Wilcox Locations

- Babcock And Wilcox Boiler Working.ppt

Main Parts:Babcock and Wilcox is a stationary water tube boiler. It has slanted cylinders which are slanted at 10 to 15 degree, which are slanted to keep up regular dissemination of water from drum to cylinders and steam from cylinders to drum.

The primary parts of this heater are as pursue. Steam separator drum:This drum is arranged upside of the kettle. It is bigger width drum in which water and steam set together.

The one portion of the drum is loaded up with water and the other half is staying for steam. Furnace:The heater is where the fuel consumes.

This is arranged at the drawback of the water tubes. At the point when the fuel consumes, the vent gases create. This gases stream upper side and goes through water tube, which warm the water and convert it into steam. Super heater:Super warmer is arranged upper side of the water tube. One end of super radiator is associated with the drum and opposite end is for process work.

Babcock And Wilcox Boiler Ppt Download

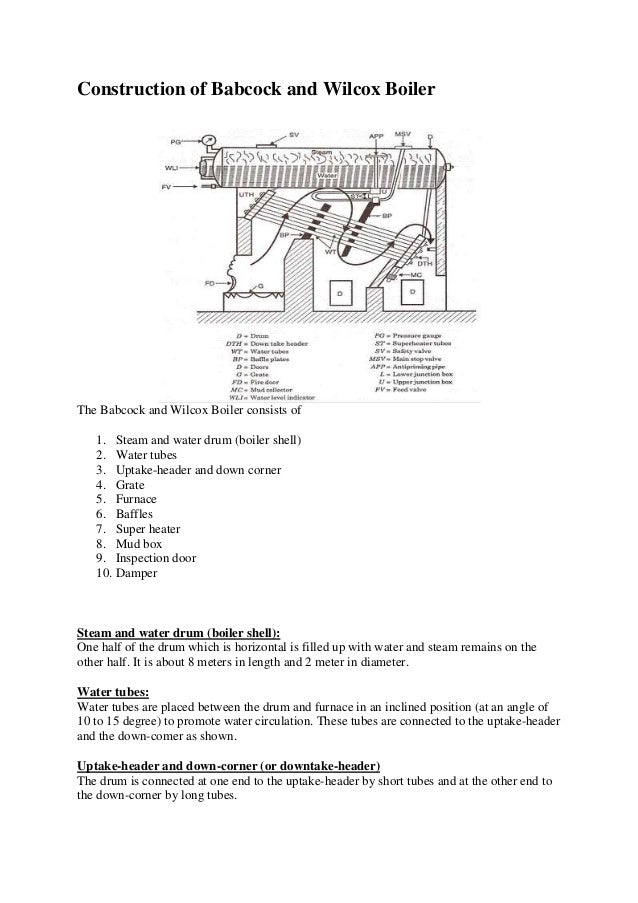

6 Construction of Babcock and Wilcox Boiler 8. Inspection door 10. DamperSteam and water drum (boiler shell):One half of the drum which is horizontal is filled up with water and steam remains on theother half. It is about 8 meters in length and 2 meter in diameter.Water tubes:Water tubes are placed between. Boiler Ppt.Monkey Business!! Babcock Wilcox Boiler YouTube. Hvac Superheat And Subcooling YouTube. Free Resume Samples & Writing Guides 2017. Free steam Boilers Training videos water tube and fire tube boilers, babcock and wilcox boilers powerplant boiler operation and maintenance training videos. Free steam Boilers Training videos water tube and fire tube boilers, babcock and wilcox boilers powerplant boiler operation and maintenance training videos. Friday, August 2 2019.

Steam streams from the drum to the super radiator, where it warmed by the vent gases and send for the procedure work. Working:Presently we examine about working of Babcock and Wilcox evaporator. This is a high weight, characteristic flow, water tube evaporator. The working of this heater is as pursue. First water is filled in the water drum through feed siphon. The drum is half loaded up with water and the upper half is for steam. First pipe is let go at the mesh.

The vent gases produce by consuming of fuel. These gases begin spilling out of one end to another finish of evaporator. The vent gases goes by the water cylinders and trade warm with water. The puzzles are given in the way, which avoids the pipe gases before getting away from the stack. Because of this avoidance, the vent gases hang loose through water tubes, which cause more warmth exchange.

The water streams from the drum to the water tube through down take header. The water tube closer to the heater warmed more than the other, so the thickness of water decline in this cylinder which makes the stream of steam from cylinder drum through take-up header. In the meantime the water from the drum goes into the cylinders through down take header.

Babcock And Wilcox Locations

The flow of water from drum to tubes and again cylinders to drum is normal, because of thickness distinction. The steam isolates in the drum at the upper half. This is soaked steam. This steam sends to the super warmer through steam pipe. The steam is warmed again by the vent gases in the super radiator and taken out for process work. The pipe gases send to the environment from the super radiator. This procedure rehash until adequate measure of steam creates.

This evaporator can produce 20 ton steam for each hour.Focal points:. The steam age rate is higher around 20 ton for every hour at weight 10 to 20 bars. The cylinders can be supplanted effortlessly.

Babcock And Wilcox Boiler Working.ppt

The evaporator can extend and contract uninhibitedly. It is anything but difficult to fix upkeep and cleaning. It dry spell misfortune is low contrasted with other kettle. The general effectiveness of this kettle is high.Sharing is caring!